- 1)

- Opening area DN 300, flanges DN 350

500-00

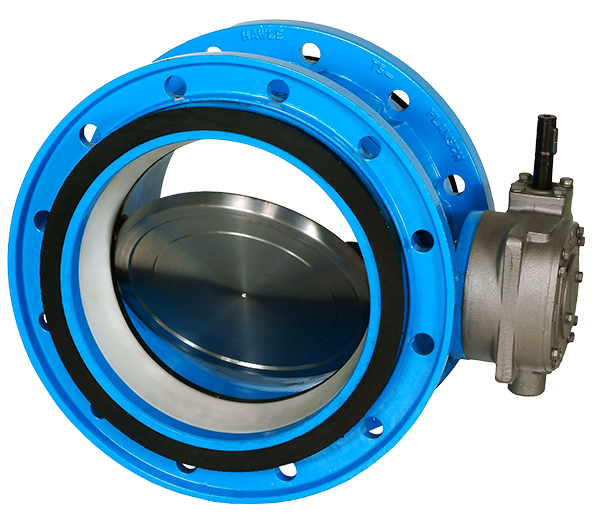

Hawle PRO butterfly valve with proportional action sealing system and restraint loose flanges

| Material: |

Body / loose flanges: GJS-400, Hawle epoxy powder coated Disc/shaft: stainless steel Seat seal: EPDM (reinforced by a ring of stainless steel) acc. to KTW-BWGL for water Supporting ring: DN 150 - DN 300: aus POM DN 400 and higher: stainless steel Barrel gasket: EPDM acc. to KTW-BWGL for water |

|---|---|

| Max. operating Pressure: | See table |

| Medium | Water |

The Hawle PRO butterfly valve is provided with a proportional action sealing system.

The sealing is accommodated in the body of the butterfly valve. When open, the same pressure is admitted to the butterfly valve from all sides, thus reliably preventing unintended deformations of the gasket. As soon as the PRO butterfly valve is moved to closed position, the valve seal is pressed against the valve disc. The contact pressure depends on the water pressure.

The proportional action sealing system ensures reliable sealing, on the one hand, and a long service life due to low wear of the sealing, on the other hand.

The Hawle PRO butterfly valve is provided with the same loose flange system as the exchange gate valve. Therefore, apart from being used in new constructions, the butterfly valve is mainly suitable for exchanging existing valves. The flat gaskets are already included in the barrel gaskets. Therefore, no keying is required between the flanges.

Moreover, the loose flange system has some advantages in terms of storage. The flanges can be quickly and easily changed from PN 10 to PN 16 or vice versa.

Apart from its real function as shut-off valve, the Hawle PRO butterfly valve can also be used as dismantling piece because of the integral loose flange system (no additional dismantling piece required).

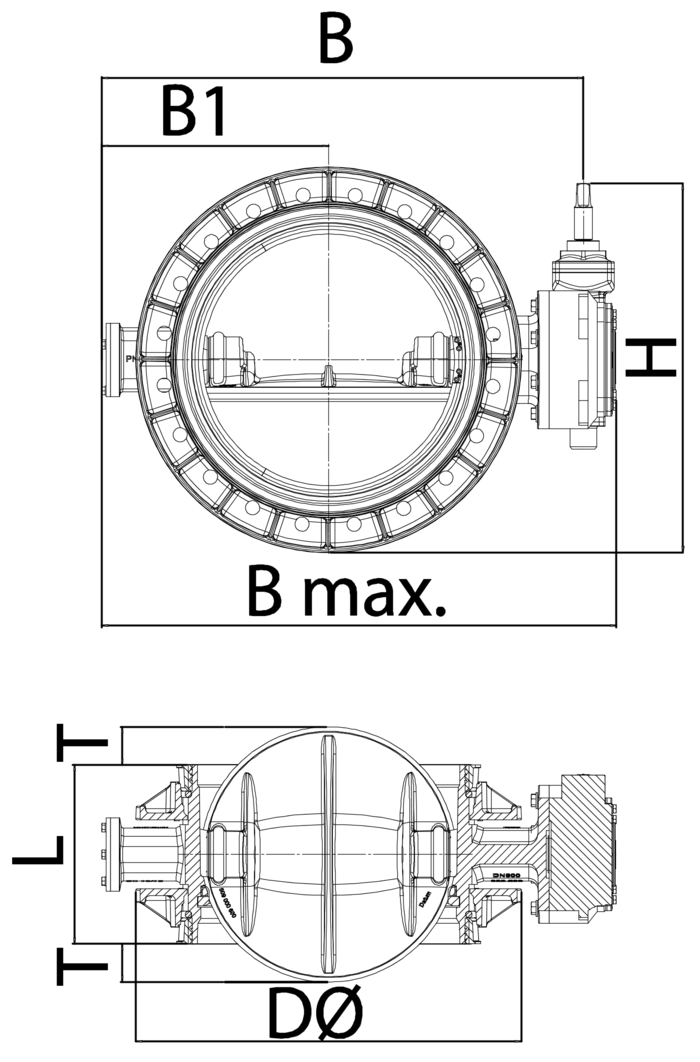

Face-to-face dimension: standard series 14 acc. to DIN EN 558-1

Flange mating dimensions: acc. to EN 1092-2

Please note: the handwheel is not included in the scope of supply (see product supplements)!

|

Order Nr.

|

*) |

DN |

PN |

L |

B |

B1 |

B max. |

H |

D � |

Unit |

T |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

|

5001500000

|

150 | 10/16 | 210 mm | 341 mm | 156 mm | 381 mm | 336 mm | 285 mm | Plant installation | 22,40 kg | |||||

|

5001501000

|

150 | 10/16 | 210 mm | 341 mm | 156 mm | 393 mm | 327 mm | 285 mm | Burried installation | 22,40 kg | |||||

|

5002000000

|

200 | 10 | 230 mm | 412 mm | 192 mm | 460 mm | 366 mm | 345 mm | Plant installation | 44,30 kg | |||||

|

5002000060

|

200 | 16 | 230 mm | 412 mm | 192 mm | 460 mm | 366 mm | 345 mm | Plant installation | 44,00 kg | |||||

|

5002001000

|

200 | 10 | 230 mm | 412 mm | 192 mm | 472 mm | 391 mm | 345 mm | Burried installation | 51,00 kg | |||||

|

5002001060

|

200 | 16 | 230 mm | 412 mm | 192 mm | 472 mm | 391 mm | 345 mm | Burried installation | 51,00 kg | |||||

|

5002500000

|

250 | 10 | 250 mm | 497 mm | 229 mm | 550 mm | 421 mm | 405 mm | Plant installation | 66,00 kg | |||||

|

5002500060

|

250 | 16 | 250 mm | 497 mm | 229 mm | 550 mm | 421 mm | 405 mm | Plant installation | 66,00 kg | |||||

|

5002501000

|

250 | 10 | 250 mm | 497 mm | 229 mm | 563 mm | 421 mm | 405 mm | Burried installation | 66,00 kg | |||||

|

5002501060

|

250 | 16 | 250 mm | 497 mm | 229 mm | 550 mm | 421 mm | 405 mm | Burried installation | 66,00 kg | |||||

|

5003000000

|

300 | 10 | 270 mm | 520 mm | 245 mm | 573 mm | 446 mm | 455 mm | Plant installation | 5 mm | 83,00 kg | ||||

|

5003000060

|

300 | 16 | 270 mm | 520 mm | 245 mm | 573 mm | 446 mm | 455 mm | Plant installation | 5 mm | 83,00 kg | ||||

|

5003001000

|

300 | 10 | 270 mm | 520 mm | 245 mm | 586 mm | 446 mm | 455 mm | Burried installation | 5 mm | 85,00 kg | ||||

|

5003001060

|

300 | 16 | 270 mm | 520 mm | 245 mm | 586 mm | 446 mm | 455 mm | Burried installation | 5 mm | 85,00 kg | ||||

|

5003500000

|

1) | 350 | 10 | 290 mm | 520 mm | 245 mm | 573 mm | 478 mm | 520 mm | Plant installation | 5 mm | 106,00 kg | |||

|

5003500060

|

1) | 350 | 16 | 290 mm | 520 mm | 245 mm | 573 mm | 478 mm | 520 mm | Plant installation | 5 mm | 106,00 kg | |||

|

5003501000

|

1) | 350 | 10 | 290 mm | 520 mm | 245 mm | 586 mm | 478 mm | 520 mm | Burried installation | 5 mm | 106,00 kg | |||

|

5003501060

|

1) | 350 | 16 | 290 mm | 520 mm | 245 mm | 586 mm | 478 mm | 520 mm | Burried installation | 5 mm | 106,00 kg | |||

|

5004000000

|

400 | 10 | 310 mm | 696 mm | 329 mm | 744 mm | 585 mm | 580 mm | Plant installation | 25 mm | 156,00 kg | ||||

|

5004000060

|

400 | 16 | 310 mm | 696 mm | 329 mm | 744 mm | 585 mm | 580 mm | Plant installation | 25 mm | 156,00 kg | ||||

|

5004001000

|

400 | 10 | 310 mm | 696 mm | 329 mm | 760 mm | 513 mm | 580 mm | Burried installation | 25 mm | 160,00 kg | ||||

|

5004001060

|

400 | 16 | 310 mm | 696 mm | 329 mm | 760 mm | 513 mm | 580 mm | Burried installation | 25 mm | 160,00 kg | ||||

|

5005000000

|

500 | 10 | 350 mm | 855 mm | 400 mm | 925 mm | 807 mm | 715 mm | Plant installation | 56 mm | 306,00 kg | ||||

|

5005000060

|

500 | 16 | 350 mm | 855 mm | 400 mm | 925 mm | 807 mm | 715 mm | Plant installation | 56 mm | 306,00 kg | ||||

|

5005001000

|

500 | 10 | 350 mm | 855 mm | 400 mm | 945 mm | 767 mm | 715 mm | Burried installation | 56 mm | 306,00 kg | ||||

|

5005001060

|

500 | 16 | 350 mm | 855 mm | 400 mm | 945 mm | 767 mm | 715 mm | Burried installation | 56 mm | 306,00 kg | ||||

|

5006000000

|

600 | 10 | 390 mm | 1049 mm | 494 mm | 1120 mm | 808 mm | 840 mm | Plant installation | 83 mm | 450,00 kg | ||||

|

5006000060

|

600 | 16 | 390 mm | 1049 mm | 494 mm | 1135 mm | 888 mm | 840 mm | Plant installation | 83 mm | 450,00 kg | ||||

|

5006001000

|

600 | 10 | 390 mm | 1049 mm | 494 mm | 1138 mm | 814 mm | 840 mm | Burried installation | 83 mm | 450,00 kg | ||||

|

5006001060

|

600 | 16 | 390 mm | 1049 mm | 494 mm | 1156 mm | 894 mm | 840 mm | Burried installation | 83 mm | 450,00 kg |

-

A = plant installation, E = buried

-

Information regarding operation via handwheel:

for DN 200 use handwheel DN 80

for DN 250 and DN 300 use handwheel DN 100

for DN 400 to DN 500 use handwheel DN 200Information regarding operation via extension spindle

:

for DN 200 to DN 500 use extension spindle DN 100 (observe pipe cover depth) -

Standard mounting situation: butterfly valve with horizontal valve disc. Butterfly valve with vertical valve disc (bearing at bottom, drive at top) on request.

-

Electric actuator / pneumatic actuator on request

-

For required bolt length see user manual

|

Operating instructions

|

|---|

| Operating instructions - Hawle PRO butterfly valve |

|

Brochures

|

|---|

| Brochure - Hawle Product Range |

|

Article Nr.

|

Product description |

|---|---|

| 200-00 | Surface box rigid version |

| 204-04 | Base plate of concrete for surface box model no. 211-00, 211-04 |

| 207-01 | Surface box for gate valves with cover, for rolling in |

| 211-00 | Surface box with cover, round |

| 211-04 | Surface box for rolling in, with locking bolt |

| 500-01 | Support bearing for Hawle PRO butterfly valve |

| 780-00 | Handwheel for gate valves and butterfly valves |

| 900-01 | Rigid extension spindle for Hawle PRO butterfly valve |

| 950-00 | Telescopic extension spindle |

| 952-00 | Telescopic extension spindle of stainless steel |