311-03

Hawle universal strap

| Material: |

Strap plate: stainless steel with rubber pad Threaded pin: stainless steel Nuts: DIN 934 - stainless steel Gripping jaws: glass fibre reinforced polyamide Saddle gasket: EPDM acc. to KTW-BWGL for water |

|---|---|

| Medium | Water / Sewage |

Hawle universal straps permit the universal connection of pipe drilling and valve saddles to DCI, steel pipes. The strap can be adapted individually to the outside diameter (d) within a certain range by cutting the strap sheet to length on site.

Therefore, the universal strap is suitable especially for "exotic" pipe outside diameters and can be used if quick installation is required and no appropriate strap is at hand. The universal strap consists of a threaded tee with welded-on sheet and rubber liner, an installation tee with a lug, as well as hexagon nuts, washers and gripping jaws. To adapt the strap to the respective pipe outside diameter, the sheet is first cut to length using a saw or metal shears. The sheet is then connected with the installation tee (metal to lug) and at last it is crimped step by step (please follow mounting instructions).

The supplied saddle gasket compensate the respective pipe diameter to the drilling saddle, thus reliably seals the borehole. The correct saddle gasket must be chosen on site.

|

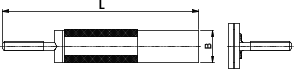

Order Nr.

|

d |

L |

B |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|

|

3110000810

|

108 - 260 mm | 810 mm | 60 mm | 1,50 kg | |||

|

3110001040

|

260 - 335 mm | 1040 mm | 60 mm | 1,65 kg | |||

|

3110001360

|

335 - 440 mm | 1360 mm | 60 mm | 2,00 kg | |||

|

3110001540

|

440 - 500 mm | 1540 mm | 60 mm | 2,20 kg | |||

|

3110001890

|

500 - 610 mm | 1890 mm | 60 mm | 2,50 kg |