227-00G

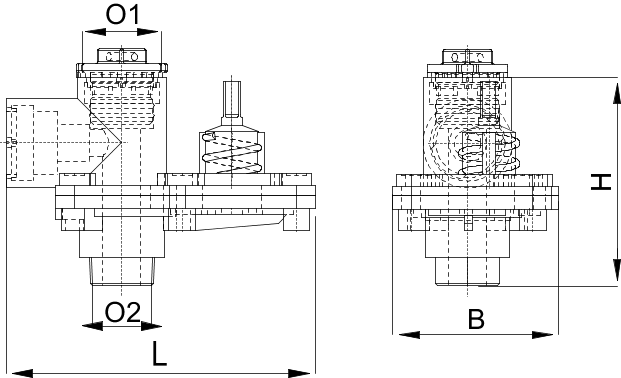

Hawlinger with upper horizontal ZAK® socket in pipe direction and lower tapered male thread or lower ZAK® spigot end for installation on pipe saddle

| Material: |

Body: GJS-400, Hawle epoxy powder coated Spindle, shut-off device, shut-off blade: stainless steel Gaskets: NBR for gas |

|---|---|

| Max. operating Pressure: | Gas: 5 bar |

| Medium | Gas |

Lower connection with ZAK® spigot end:

Hawlinger with lower ZAK® spigot end for the restraint connection in pipe drilling saddles with ZAK® socket (e.g. universal pipe drilling saddle, model no. 352-00)

Lower connection with male thread:

Hawlinger with lower tapered male thread for installation in pipe drilling saddles with cylindrical female thread (e.g. universal pipe drilling saddle, model no. 352-01)

In combination with ZAK® spigot end fittings, the upper ZAK® socket outlets are used to connect service lines.

All Hawle pipe drilling saddles type Hawlinger are provided with a shut-off blade of stainless steel driven via slotted link gear as shut-off device. The shut-off blade is moved in a housing at low wear in horizontal direction against fixed metal stops.

To open or close the outlet area only one half revolution (180°) is required.

In combination with a tapping device suitable for gas, the shut-off system enables the simple tapping of a pipeline, even in the operating state.

Square of spindle: 12,3 mm

|

Order Nr.

|

L |

Description |

B |

H |

Borehole max. |

Outlet O1 |

Outlet O2 |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|---|---|---|---|

|

2270500465

|

230 mm | 123 mm | 160 mm | 28 mm | ZAK 46 | ZAK 46 | 5,95 kg | ||||

|

2270500505

|

230 mm | 123 mm | 155 mm | 28 mm | ZAK 46 | AG 1 1/2" konisch | 5,80 kg | ||||

|

2270500635

|

230 mm | 123 mm | 155 mm | 36 mm | ZAK 46 | AG 2" konisch | 5,60 kg | ||||

|

8700000000

|

Surcharge for spindle bore | 0,00 kg |