-

Optional with 4 x female thread 3/8".

-

Strainers are designed for installation in horizontal pipelines. Installation in inclined and vertical pipelines is permitted if the flow direction is from top to bottom (observe arrow at the body).

019-02

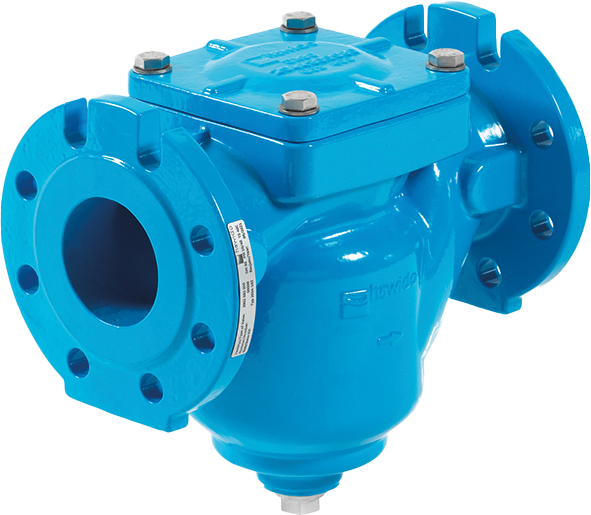

Strainer, top cover

| Material: |

Body and cover: GJS-400, epoxy powder coated Strainer element: stainless steel Emptying plug: stainless steel Gaskets: EPDM acc. to KTW-BWGL for water |

|---|---|

| Max. operating Pressure: | See table |

| Medium | Water |

Screen mesh size:

0.6 mm (standard),

2.0 mm and 5.0 mm (on request)

Face-to-face dimension: standard series 1 acc. to DIN EN 5581

Flange mating dimensions: acc. to EN 1092-2

Temperature of medium: 0 - 40°C

Description

The strainer protects pipelines and valves against the unwanted intrusion of “foreign matter” (e.g., wood, stones, drilling chips, etc.). Generally, we recommend the installation of a strainer upstream of each control valve, measuring device, or unit to ensure the proper functioning of the control valve.

The flow-optimized strainer consists of a valve body with flange connection, a strainer screen placed inside, and the cover on top. The screen placed inside retains and collects dirt loads carried in the medium of potable water.

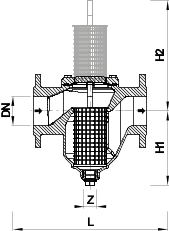

Important: For overhaul (dismantling of the screen), sufficient working space of H2 must be provided above the strainer, from the pipe axis to the chamber ceiling!

|

Order Nr.

|

DN |

PN |

L |

H1 |

H2 |

Medium | Weight | Specification | Basket |

|---|---|---|---|---|---|---|---|---|---|

|

190004040

|

40 | 40 | 200 mm | 163 mm | 227 mm | 11,10 kg | |||

|

190005040

|

50 | 40 | 230 mm | 162 mm | 225 mm | 12,60 kg | |||

|

190006540

|

65 | 10/16 | 290 mm | 203 mm | 275 mm | 17,50 kg | |||

|

190008040

|

80 | 40 | 310 mm | 206 mm | 300 mm | 24,50 kg | |||

|

190010040

|

100 | 10/16 | 350 mm | 228 mm | 355 mm | 30,00 kg | |||

|

190012540

|

125 | 10/16 | 400 mm | 277 mm | 455 mm | 46,00 kg | |||

|

190015040

|

150 | 10/16 | 480 mm | 326 mm | 535 mm | 63,00 kg | |||

|

190020040

|

200 | 10 | 600 mm | 397 mm | 697 mm | 109,00 kg | |||

|

190020050

|

200 | 16 | 600 mm | 397 mm | 697 mm | 109,00 kg |

|

Operating instructions

|

|---|

| Operating and maintenance instructions - strainer top cover |